Custom PCB Shapes using Eagle

-

Hello,

I'm working on a PCB design that uses ESP32 processor. I want to make a custom PCB shape using Eagle(It's by default an arbitrary rectangle in eagle though). How can i make different shapes like circle, Hexagon or any custom PCB shape? Is it possible with Trail version of Eagle ? -

Hi @kowshik1729,

Yes, you can import the .dxf drawings file to PCB Board design, but I recommend is that use Autodesk Fusion360, you can collaborate with eagle .

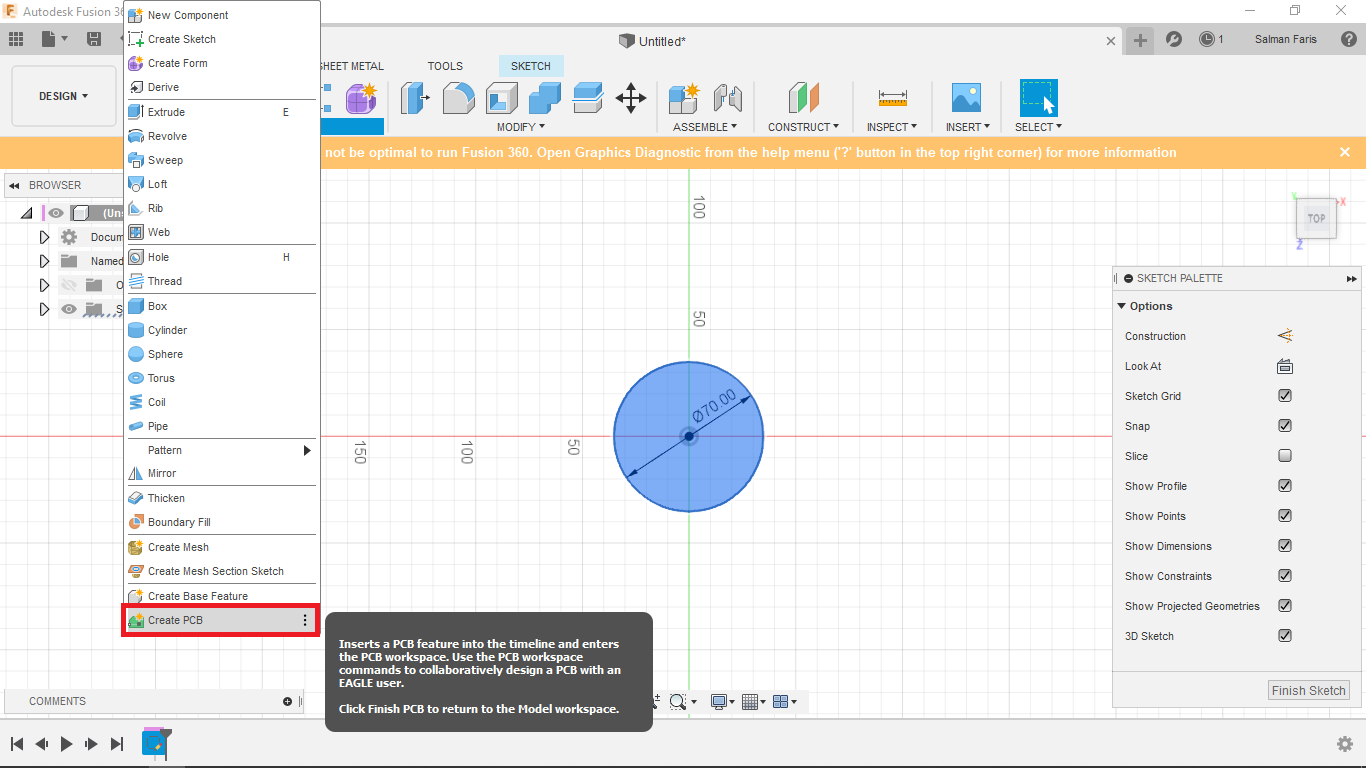

Step 1: Create Fusion360 design

Step 2: Select Creat PCB from Creat -> Create PCB

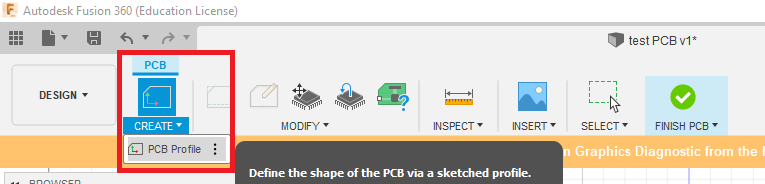

Step 3: Click Create PCB Profile

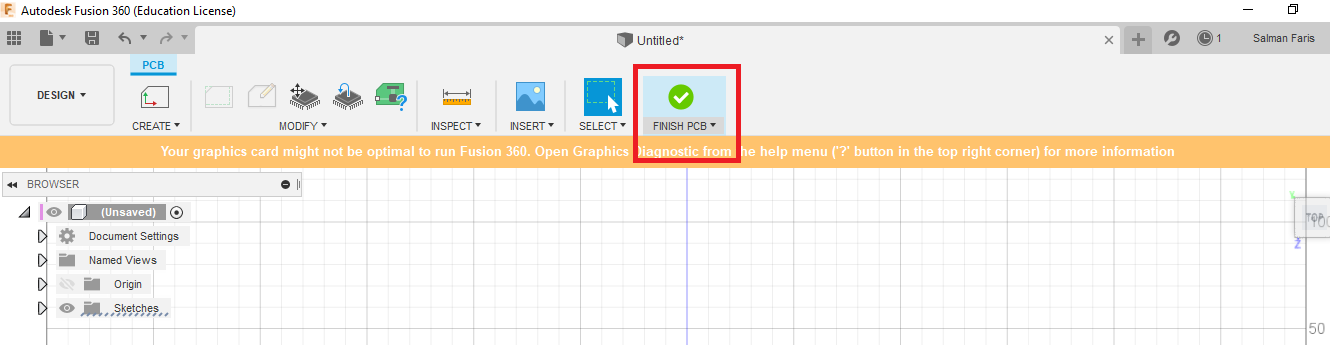

Step 4: Click Finish PCB and Save to Fusion

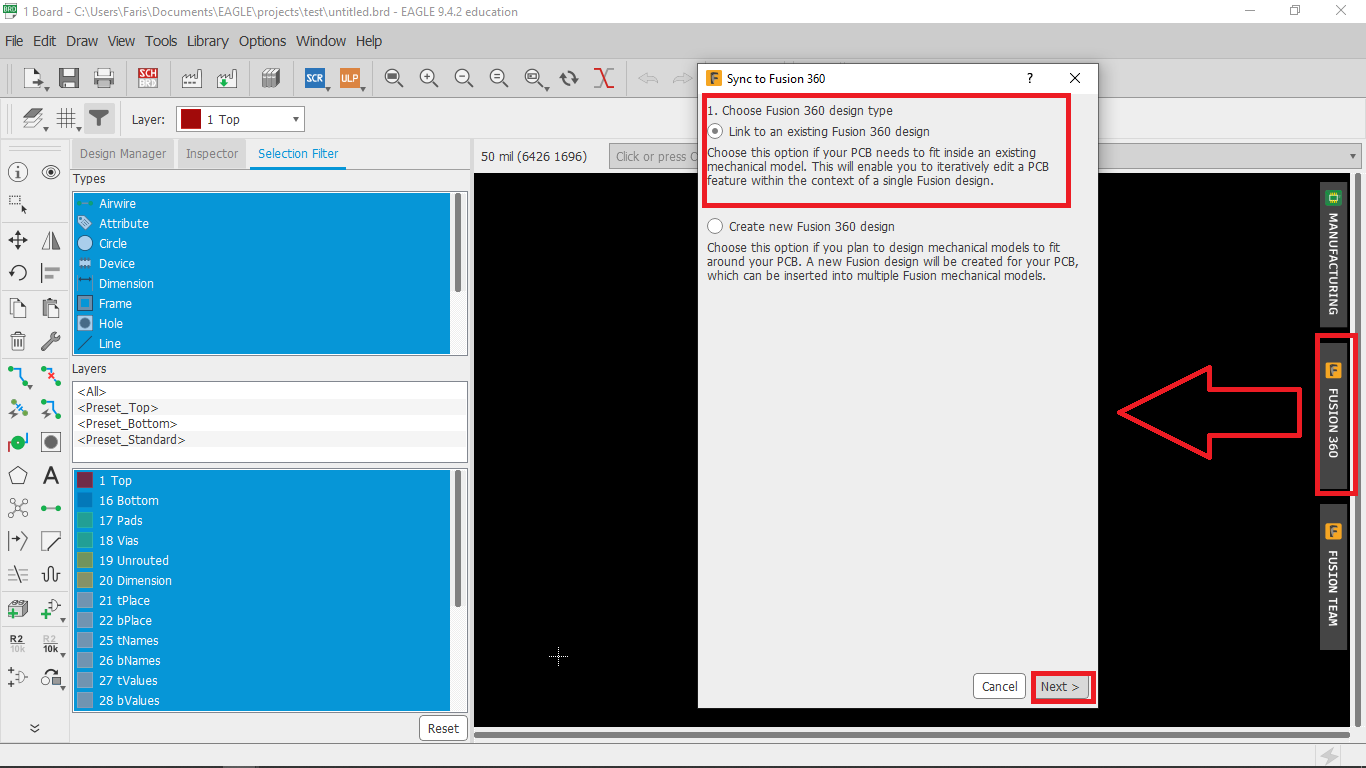

Step 5: Open Eagle and Sign with the same account that used Fusion360

Step 6: Open Board Design file and Select Fusion360 Icon on the right side and Select Option One that links to existing fusion design

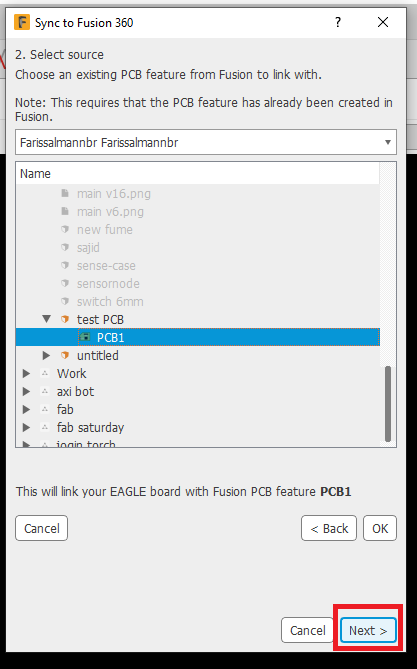

Step 7: Select Fusion Project from the following project list and select the PCB file

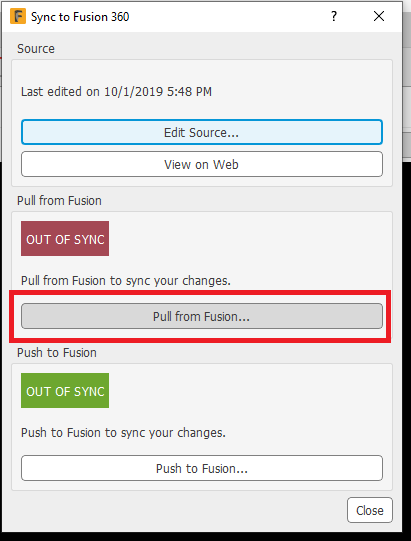

Step 8: Click Pull From Fusion to Sync the design with Eagle

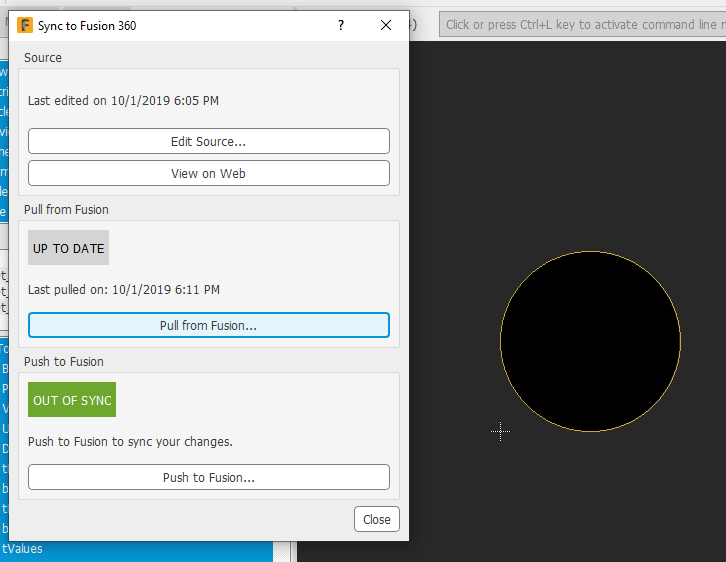

Step 9: If everything done perfectly you can see the PCB board outline in eagle

All the best

-

@salmanfaris Woow, thank you soo much. This is very explanatory...!!